Denso 190DP Epoxy Grout: The Ultimate Solution for Vibration Dampening for Heavy Machinery

Maintaining optimal performance and structural integrity for heavy machinery requires more than just your standard baseplate. Industrial equipment foundations demand a high-strength material that can withstand extreme loads, temperature fluctuations, and continuous vibration, all while preserving long-term precision and alignment required to keep a machine running smoothly. Denso 190DP Epoxy Grout is just that, an advanced, high-strength, three-part epoxy system specifically engineered to meet these complex demands for heavy machinery baseplate through this deep pour grout.

Advanced Low Exotherm Technology

The advanced low-exotherm formulation of Denso 190DP Epoxy Grout is one of its strongest differentiators in the market, giving it a performance edge over traditional epoxy grouts. By generating significantly less heat during cure, 190DP minimizes thermal stress on both the grout and the equipment being set, reducing the risk of cracking, shrinkage, or substrate damage—issues that are common with high-exotherm competitor products, especially in large or deep pours. This controlled heat profile also allows for safer, more predictable installations, improved working time, and the ability to handle heavy-duty applications without compromising mechanical strength. In environments where precision, longevity, and equipment integrity are critical, the low-exotherm chemistry of Denso 190DP is a key reason it consistently outperforms conventional epoxy grouts.

Superior Load Distribution and Equipment Alignment

Denso 190DP Epoxy Grout’s excellent bearing area ensures maximum contact with the equipment base, delivering superior load distribution that preserves precise alignment over the long term. By minimizing point-loading and dampening operational vibration, Denso 190DP significantly reduces the risk of structural damage, loosening, or premature failure. This enhanced bearing performance translates into longer equipment life, fewer unplanned shutdowns, and lower maintenance costs—an advantage that sets Denso 190DP apart from conventional grouts.

Enhanced Vibration Dampening Performance

Industrial facilities constantly battle equipment-generated vibrations that can undermine structural integrity and accelerate wear. Denso 190DP Epoxy Grout’s high-strength, precision-engineered formulation provides superior vibration dampening, significantly reducing vibration transmission into foundations and surrounding structures. By minimizing these dynamic forces, 190DP helps prevent mechanical failures, maintains smoother equipment operation, and protects critical infrastructure from long-term vibration-related damage.

Rapid Strength Gain for Minimal Downtime

Time is critical in industrial installations, and Denso 190DP Epoxy Grout addresses this need with engineered rapid strength gain properties. This feature allows facilities to complete installations with minimal downtime, accelerating project schedules and improving overall productivity. The quick-setting characteristics don’t compromise long-term durability, ensuring both immediate and sustained performance.

Chemical and Corrosion Resistance

Industrial environments often expose grouting materials to harsh chemicals and moisture conditions. Denso 190DP Epoxy Grout stands out with robust corrosion and chemical resistance properties, ensuring consistent, reliable performance in the harshest settings exposed to chemicals and moisture. This resistance extends the service life of installations while maintaining structural integrity under challenging operating conditions.

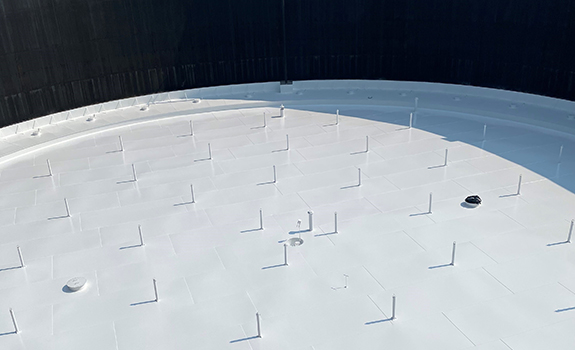

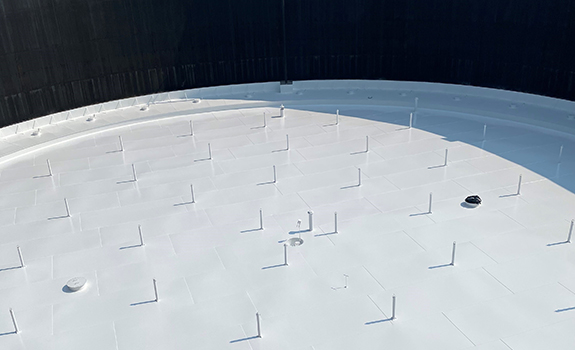

Large Volume Precision Placement Benefits

Denso 190DP Epoxy Grout is engineered for large-volume precision placement, delivering consistent flow and controlled viscosity that allow installers to achieve exact leveling and alignment even in deep or expansive pours. Its advanced formulation ensures uniform consolidation under baseplates and around anchors or dowels, creating a stable, void-free foundation that supports the long-term performance of heavy machinery. By enabling accurate placement at scale, Denso 190DP reduces installation errors, enhances equipment efficiency, and minimizes future maintenance—making it a superior choice for demanding industrial applications where precision and reliability are non-negotiable.

Setting a New Standard in Industrial Grouting

Denso 190DP Epoxy Grout is redefining expectations for grout performance in the heavy machinery and industrial equipment sector. By combining advanced low-exotherm chemistry, uniform load transfer & high effective bearing area, exceptional vibration dampening, and true large-volume precision placement, it delivers a level of reliability and installation confidence that traditional epoxy grouts simply cannot match. Engineered for the most demanding environments, Denso 190DP provides the long-term stability, accuracy, and durability required to keep mission-critical equipment operating at peak performance. With its unmatched blend of safety, strength, and precision, Denso 190DP is poised to set a new industry standard—raising the bar far beyond what competitors can offer.

For more information about Denso 190DP Epoxy Grout, CLICK HERE

DENSO® 190DP Epoxy Grout — engineered to absorb vibration, stabilize heavy machinery, and extend equipment life in demanding industrial environments.

Archco 476 High-Performance Phenolic-Novolac Epoxy Linings Deliver Industry-Leading Chemical and Temperature Resistance

Denso, Inc., a global leader in corrosion prevention, is proud to highlight its Archco 476 Series™, a comprehensive range of high-performance, two-part phenolic-novolac epoxy linings formulated to safeguard tanks and piping systems in the most demanding environments. The Archco 476 Series sets a benchmark for corrosion protection and long-term asset performance, harnessing cutting-edge epoxy technology and robust development to ensure advanced resistance to chemical, high pressures and high service temperatures.

Designed specifically for applications where internal linings must withstand extreme temperature conditions, the Archco 476, 476F, 476LT, and 476P Epoxy products each offer a distinct set of technical advantages tailored to industry needs. Each formula in the series provides exceptional corrosion protection for steel tanks, vessels, and pipes, ensuring reliable defense against crude oil, seawater, wastewater, fuels, solvents, and lubricants. All systems within the range exhibit excellent adhesion and outstanding chemical resistance, delivering high temperature immersion protection up to 275°F (135°C) where specified and maintaining performance over a broad spectrum of operating pressures.

The standard Archco 476 Epoxy features an 85% solids composition optimized for single-leg airless spray application, providing robust service life and fast cure cycles that minimize downtime. For lining applications requiring enhanced durability and reinforcement, Archco 476F Epoxy integrates a proprietary blend of flake and fiber, meeting API RP 652 guidelines for thick-film linings and offering excellent abrasion and impact resistance. This reinforced formula ensures resilience in harsh, high-abrasion service up to 250°F (121°C), making it the ideal choice for environments exposed to mechanical stress or volatile materials.

For installations where ambient temperatures pose a challenge, Archco 476LT Epoxy allows plural-component spray application at temperatures as low as 20°F (-7°C), supporting projects that require expedited return to service and cold-weather functionality. Its 100% solids content and fast cure ensure efficient project turnaround without sacrificing protective qualities, even in challenging field conditions. The Archco 476P Epoxy offers a specialized plural-component, 100% solids solution engineered for high-build applications up to 40 mils DFT. Zero VOC emissions make this solution compliant with stringent regulations, while its high temperature and chemical resistance offer peace of mind for specifiers working in environmentally controlled sectors.

The Archco 476 Series™ delivers cathodic disbondment resistance, helping prevent underfilm corrosion and amplifying long-term asset reliability. Each system is designed for straightforward field application and dependable adhesion, withstanding aggressive chemical and temperature fluctuations. With this advanced solution, Denso reinforces its commitment to delivering innovative, high-performance solutions for industrial infrastructure protection.

For more information about the Archco 476 Series™, please visit www.densona.com.

Archco 476 Series™ – The Ultimate Two-Part Epoxy Phenolic-Novolac Tank Lining Solution”

Archco 381 Delivers High Gloss and Lasting Protection for Industrial and Marine Assets

Archco 381 is a high-gloss, hybrid exterior topcoat developed to provide outstanding protection and visual appeal for a wide range of industrial and marine assets. This high-solids, two-part coating is specifically designed to incorporate the best characteristics of polyurethane coatings, including high gloss, exterior durability, chemical resistance, solvent resistance, mar resistance, and flexibility. Uniquely, Archco 381 achieves these results while being completely isocyanate-free and offering excellent gloss retention, making it a standout solution for asset protection in challenging environments.

Versatile Applications

Archco 381 is engineered for use on storage tanks, offshore and marine structures, structural steel, railcar exteriors, aboveground pipelines, and for general industrial maintenance. It is also suited as a topcoat for Protal and Archco coatings. Its versatility allows it to be used both in new construction and in maintenance projects, providing reliable protection and a high-quality finish across multiple sectors.

Key Features and Performance

One of the primary advantages of Archco 381 is its isocyanate-free formulation, which enhances safety during application and use. The coating can be applied in a single coat to properly prepared, previously painted surfaces, or it can be used direct-to-metal, streamlining the application process and reducing labor time. Archco 381 delivers excellent gloss and color retention, ensuring that coated surfaces maintain their appearance even after prolonged exposure to harsh conditions. It’s good corrosion and chemical resistance further extend the life of critical infrastructure, and its excellent recoat properties provide flexibility for ongoing maintenance needs.

Surface Preparation and Application

Proper surface preparation is essential for maximizing the performance and durability of Archco 381. Surfaces should be at least 40°F (4°C) prior to application, dry, clean, and free of oil, grease, and other contaminants. For direct-to-metal or existing substrates, a pressure wash is recommended. For optimal adhesion, it is advised to prime with Archco 300 Primer at a dry film thickness of 4 to 8 mils.

Archco 381 is supplied as a two-part kit and should be thoroughly mixed with a power agitator before use. Application can be performed by roller, brush, or airless spray, with the coating typically applied at a film thickness of 10 to 12 mils wet (6 to 8 mils dry) in a single coat. The pot life at 77°F (25°C) is four hours, and equipment should be cleaned with MIBK or MEK after application.

Storage and Safety

For best results, Archco 381 should be stored in original, unopened containers in a dry, well-ventilated area between 40°F and 90°F (4°C and 32°C). The shelf life is at least twelve months under these conditions. It is recommended to bring all components to between 68°F and 86°F (20°C and 30°C) for 24 hours prior to use to ensure optimum pumping and productivity. During application, wear protective clothing and ensure adequate ventilation to avoid contact with skin and eyes.

Why Archco 381 Is the Smart Choice for Your Next Project

When it comes to protecting your most valuable assets, Archco 381 brings together the best of both worlds: striking high-gloss aesthetics and the rugged performance needed for harsh industrial and marine environments. Its isocyanate-free formula, straightforward application, and proven durability make it a go-to solution for maintenance teams and asset owners who want a coating that looks great and performs even better. If you are ready to upgrade your protective coatings, Archco 381 is ready to deliver the results you need.

Archco 318 used on a storage tank for high performance exterior coating.

Floating roof tank protected with Archco 381 top coat.

Advanced Pipeline Coating Protection: Denso’s Bore-Wrap® for Challenging Environments

In the ever-evolving world of pipeline installations, protecting infrastructure against corrosion and damage is paramount. Enter Bore-Wrap®, the latest innovation from Denso, Inc., a global leader in corrosion prevention. This cutting-edge, field-applied abrasion-resistant outerwrap (ARO) is set to transform how we approach pipeline protection in challenging environments.

Why Bore-Wrap Matters

Unparalleled Protection

Bore-Wrap offers exceptional mechanical protection for anti-corrosion coatings during pipeline installations in difficult terrain or when using trenchless installation methods. Its robust design shields against shearing, abrasion, impact, and gouge, making it an ideal choice for various anti-corrosion coatings, including FBE, epoxies, shrink sleeves, 3LPE, and 3LPP.

Versatility in Application

As a field-applied ARO, Bore-Wrap provides unmatched flexibility for various installation methods:

- Horizontal Directional Drilling (HDD)

- Boring

- Thrust Boring

- Microtunneling

- Trenchless Installation

This versatility makes Bore-Wrap an essential tool for pipeline projects across diverse and challenging terrains.

Benefits for the Industry

Cost-Effective Solution

By creating an abrasion-resistant, sacrificial outer laminate, Bore-Wrap significantly reduces the need for spot repairs or re-pulling pipe due to damage. This protection ensures the integrity of underlying coatings, minimizing project downtime and associated costs.

Operational Efficiency

Bore-Wrap’s ease of application in the field enhances operational efficiency. It’s designed to work seamlessly with a wide range of field joint coatings and shrink sleeves, making it a versatile choice for various pipeline projects.

Industries Benefiting from Bore-Wrap

Bore-Wrap is set to make waves in several key industries where pipeline integrity is crucial:

- Oil and Gas

- Water

- Petrochemical

For contractors and operators facing the challenges of complex pipeline installations, Bore-Wrap represents a significant advancement in protection technology.

Conclusion

As we continue to push the boundaries of pipeline installations in increasingly challenging environments, solutions like Denso’s Bore-Wrap become indispensable. By providing superior mechanical protection, Bore-Wrap ensures the longevity and integrity of pipelines, even in the most demanding conditions. This innovative product not only revolutionizes pipeline protection but also sets a new standard for safety and efficiency in the industry. For those looking to stay ahead in pipeline protection technology, Bore-Wrap offers a reliable, versatile, and cost-effective solution that promises to transform the landscape of pipeline installations for years to come.

. Denso Bore-Wrap creates an abrasion resistant, sacrificial outer laminate which protects pre-approved field joint coatings and mainline coatings such as epoxies, shrink sleeves, 3LPE, 3LPP and FBE.

Densoband™ Setting a New Standard in Joint Sealing for Road and Pavement Construction

When it comes to building and maintaining roads, bridges, and runways, even the smallest details can make a significant difference in long-term durability. Joint sealing is one of those critical details-essential for protecting infrastructure from water ingress, erosion, and costly repairs. Densoband™ is a high-performance solution engineered to address these challenges and deliver lasting results.

Why Joint Sealing Matters

Roads and pavements are constantly exposed to heavy traffic, temperature fluctuations, and environmental stress. Without proper joint sealing, water and debris can penetrate vulnerable areas, leading to erosion, cracking, and structural damage. Densoband is designed to prevent these issues, offering a durable and effective barrier that safeguards your investment.

A real-world example of the importance of joint sealing can be seen in the Costco Wholesale case study. As the second largest retailer in the world, Costco faced concerns over heaving asphalt and potential customer injury and liability at their Orillia, Ontario location. To address these risks, Costco adopted Densoband to protect all asphalt-concrete joints around their buildings and gas stations throughout North America.

What Makes Densoband Different?

Densoband is a hot asphalt bituminous sealing strip developed for sealing joints between asphalt, concrete, and steel surfaces. Its unique polymer-modified bitumen composition provides outstanding flexibility and durability, allowing it to accommodate movement from heavy traffic and thermal changes. This ensures a uniform, watertight, and flexible seal that stands up to the harshest conditions.

In the Costco Orillia project, more than 500 linear meters of Densoband were installed around the apron of the building and the gas station. The product acted like a gasket, protecting joints from water infiltration and the damaging effects of freeze/thaw cycles, thereby prolonging the life of asphalt joints and preventing hazards to patrons.

Key Features

- Excellent Flexibility: Accommodates expansion, contraction, and movement without cracking or propagating damage.

- Uniform Watertight Seal: Prevents water ingress, reducing erosion and joint deterioration over time.

- Excellent Adhesion: Bonds strongly to primed asphalt, concrete, or steel for long-lasting performance.

- High Durability: Withstands heavy traffic loads and environmental stressors-ideal for high-traffic areas.

- Easy, Safe Installation: Integrated adhesive system eliminates the need for flame application, improving safety and efficiency.

- Versatile Application: Can be applied by hand or machine to suit a wide range of project requirements.

- Minimal Maintenance: Reduces long-term maintenance costs and extends the lifespan of infrastructure.

- Reliable in All Climates: Performs in temperatures from +41°F (+5°C) to +113°F (+45°C) and remains crack-free even at (32°F) 0°C.

Where Densoband Excels

Densoband is the go-to solution for a variety of infrastructure applications, including:

- New road construction and maintenance

- Bridge repairs

- Parking lot sealing

- Railways

- Airport runways

Its versatility and reliability make it indispensable for engineers and contractors seeking durable joint sealing technology that stands up to challenging conditions.

Costco’s adoption of Densoband across its North American facilities highlights its effectiveness in high-traffic commercial environments. By choosing Densoband, Costco proactively addressed the most vulnerable areas of their asphalt installations, ensuring long-term protection against water infiltration and freeze/thaw damage.

Ready to Upgrade Your Joint Sealing?

If you’re looking for a reliable, cost-effective, and easy-to-install solution for your next infrastructure project, Densoband is ready to deliver. Experience the difference that high-performance technology can make when you choose Densoband for your next road, bridge, or runway project. Invest in long-lasting protection and quality for your infrastructure needs.

Click Here for more info over Denso’s Densoband Sealing Strips.

Hot Asphalt Joint Sealing Compound.

Protecting Your Tank Base: A Game-Changing Solution from Denso

If you’re in the business of managing above-ground storage tanks, you know the headache that tank base corrosion can cause. It’s not just a minor inconvenience – it’s a serious threat to structural integrity, environmental safety, and your bottom line. But what if there was a cutting-edge solution that could change the game?

The Viscotaq Tank Base Corrosion Protection System

Denso, Inc., a leader in corrosion prevention technologies, has introduced an innovative system designed to tackle this persistent problem head-on. The Viscotaq Tank Base Corrosion Protection System offers a durable, moisture-resistant barrier that safeguards the critical tank chime area.

Why It Matters

This system isn’t just about preventing corrosion – it’s about extending tank lifespans, reducing maintenance costs, and minimizing safety and environmental risks. By creating a flexible, self-adhering barrier, the Viscotaq system keeps water and contaminants at bay, protecting your assets and your peace of mind.

Key Features That Set It Apart

The Viscotaq system boasts a simplified, four-part application process that’s as effective as it is easy to use:

- Viscotaq Adhesion Promoter: A quick-drying primer that ensures maximum adhesion to both the tank chime and concrete base.

- ViscoMastic or ViscoMastic XHT: A non-toxic, conformable mastic that seals gaps and cracks. It’s self-healing, flexible, and fire-retardant. For high-temperature environments up to 257°F (125°C), the XHT variant is available.

- Viscotaq EZ-Wrap: A visco-elastic coating with a paintable backing, providing complete coverage with a weatherboard overlap for maximum moisture protection.

- Archco Topcoats: These flexible, durable finishes come in two options:

- Archco 15: A UV-resistant acrylic topcoat for applications up to 150°F (65°C)

- Archco 65: A polyurethane topcoat offering superior chemical resistance for temperatures up to 200°F (93°C)

Durability Meets Versatility

What makes the Viscotaq system truly stand out is its ability to resist mechanical damage, corrosion, and harsh environmental conditions. Whether you’re dealing with high temperatures or chemical exposure, this modular system has you covered. Plus, it enhances the aesthetic appearance of your tanks – because who says industrial equipment can’t look good?

The Expert’s Take

Edwin Welles, Vice President of Viscotaq products, puts it best: “The Viscotaq Tank Base Protection System delivers unmatched performance for tank base protection. By combining advanced materials with a simple application process, we’re providing operators with a reliable, cost-effective way to protect critical infrastructure.”

Wrapping Up

In the world of tank base protection, the Viscotaq Tank Base Corrosion Protection System is a true game-changer. It offers superior protection, ease of use, and the versatility to meet diverse environmental demands. If you’re looking to safeguard your tank bases and optimize your operations, this system deserves your attention.

Remember, protecting your assets isn’t just about preventing problems – it’s about investing in the longevity and efficiency of your operations. With solutions like this, the future of tank base protection looks brighter than ever.

Click Here for more info over Denso’s Tank Base Protection System.

Protecting Your Tank Base: A Game-Changing Solution from Denso.