CASE STUDY

Gulf of Mexico Offshore Oil Platform – Offshore Platfom Steel Pile Protection

FX-70 Used to Protect Steel Piles from Splash Zone Corrosion

Project Data

| Location | Gulf of Mexico |

| Completion | July - 1977 |

| Project Type | Offshore Platform Steel Pile Corrosion Protection |

| Products Used | FX-70 System |

This Gulf of Mexico oil platform, located approximately one hundred miles East of Freeport, Texas, required in-place splash zone corrosion protection. The FX-70® System was specified after other systems had been attempted and abandoned because of heavy seas and other problems associated with offshore operations.

The first phase installation was accomplished in fourteen days in the field and involved protecting fourteen diagonals and kneebraces with two-size foot jackets each back in July 1977.

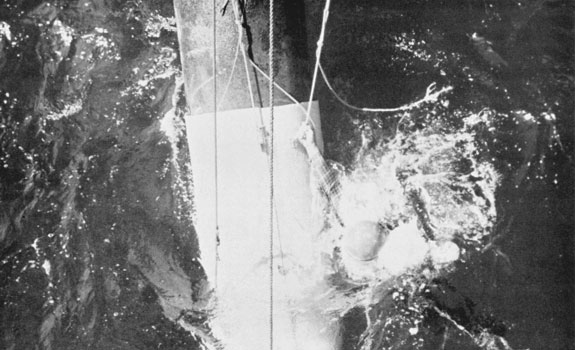

FX-70 System helps stop splash zone corrosion on Gulf of Mexico offshore oil platform.

Jackets were fabricated in two foot sections and ranged in diameter from 18 to 33 inches.

FX-70 jackets are easily handled in the field and spread easily for application of bonding material or encapsulation of member to be protected.

Installation time in the difficult wave band is reduced with the FX-70 System.

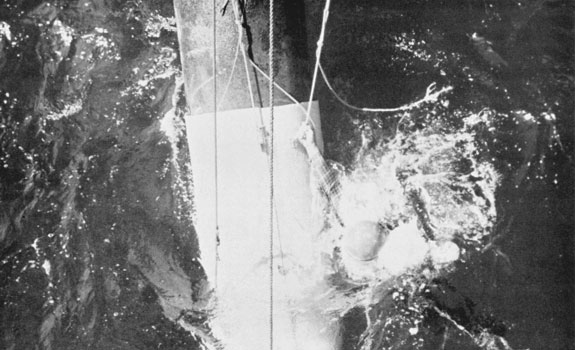

FX-70 system providing splash zone corrosion protection to this steel offshore pile.

FX-70 System helps stop splash zone corrosion on Gulf of Mexico offshore oil platform.

Jackets were fabricated in two foot sections and ranged in diameter from 18 to 33 inches.

FX-70 jackets are easily handled in the field and spread easily for application of bonding material or encapsulation of member to be protected.

Installation time in the difficult wave band is reduced with the FX-70 System.