CASE STUDY

Protal 7200 Protects Kinder Morgan’s Canadian Buried Pipeline

Buried Pipeline

Project Data

| Location | Canada |

| Completion | 2008 |

| Project Type | Buried Oil Pipeline |

| Products Used | Protal™ 7200 |

| Contractor or Applied By | North American Construction |

Project Details

The development of the mining business for extracting oil from the oil rich sands of the Canadian North is continuing at a rapid pace. More mine sites are being built and new mega-projects are being announced as the world is beginning to recognize Canada as a safe and reliable resource of oil. Countries such as the United States and China and their great demand for the resource is one of the big driving factors influencing the growth of Alberta’s Oils lands.

Part of the equation of the export of Canadian oil is the construction of the infrastructure required to move the oil, in its various states of refinement, to different markets around the world. Pipelines are being utilized as the primary mode of transportation for the initial movement of product to refineries throughout Canada and the U.S.. Pipelines are also utilized as the carrier to get liquids to ocean ports, primarily along the Western Coast of Canada, where it can be loaded onto ocean as these projects represent enormous investments of time and money. Failures of these lines are extremely expensive and can have huge environmental impacts.

Denso North America is currently involved with one of these pipeline projects as the selected supplier of liquid epoxies used as an external corrosion barrier on girth-welds, transition fittings as well as on joints of pipe that were not plant coated with FBE. The ‘Anchor Loop’ project is the initial phase of Kinder Morgan’s TMX (Trans-Mountain X-ing) which when completed will run from Edmonton, Alberta to Vancouver, British Columbia. It is a significant project for a number of reasons, one of which is that it runs through one of Canada’s National Parks and is an extremely environmentally sensitive area; also the fact that it crosses the Rocky Mountains provides challenges in itself. Another important aspect of the project is that it strengthens Canada’s position to increase flow of liquids to west coast terminals.

North American Construction is the pipeline contractor responsible for building the line having the experience and equipment to handle a job of this magnitude. North American’s Denso Certified Coating Teams have the job of hand applying the Denso Protal 7200 to over 10,000 joints and transition fittings in a variety of climatic conditions. For many days North American crews are working in minus 30 degree Celsius temperatures. It takes serious equipment and manpower and a serious coating to take on a project like this. Denso Protal 7200 (brush applied) and Protal 7250 (spray applied) is a time-tested 100% liquid epoxy which has proven itself to the pipeline and energy companies which encompass the oil and gas industry of Canada and because of this, Protal is often the coating of choice for major Oils lands projects. Denso meets and exceeds both the technical requirements and practical application criteria for pipelining in the rugged North.

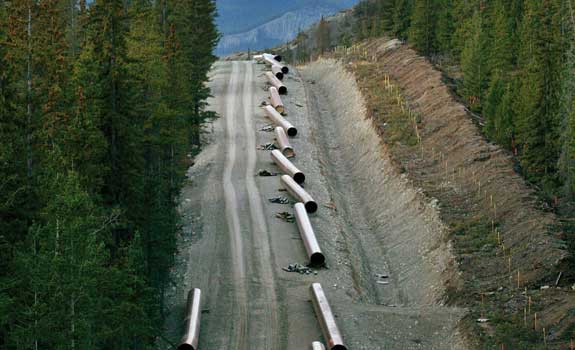

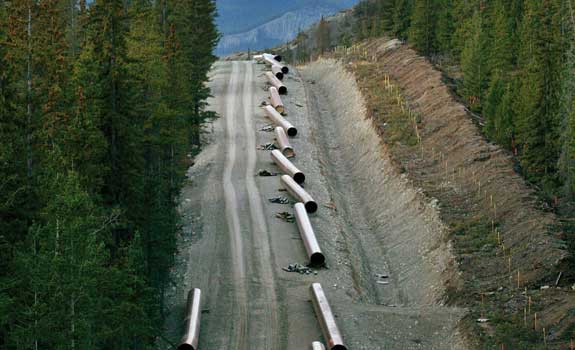

Pipe lengths awaiting Denso Protal™ application, mark out the route through the stunningly beautiful and environmentally sensitive Canadian National Park.

The pipe lengths are welded together and the welded joint areas are then coated with Denso Protal™ 7200 before being buried.

Pipe lengths awaiting Denso Protal™ application, mark out the route through the stunningly beautiful and environmentally sensitive Canadian National Park.