CASE STUDY

Bending and Compression Test Show Increased Load Strength to Timber Piles Using SeaShield Series 400 System

Product & Series Testing

Project Data

| Location | Texas A&M University |

| Completion | 2017 |

| Project Test | Test Program for Rehabilitation of Deteriorated Timber Piles Using the SeaShield Series 400 System |

| Products / System Tested | SeaShield™ Series 400 System - SeaShield Fiber Form Jackets, Sea-Shield 510 UW Grout and C-GRID® 450 Carbon Fiber Grid |

2008 Timber Piles Tested in Bending

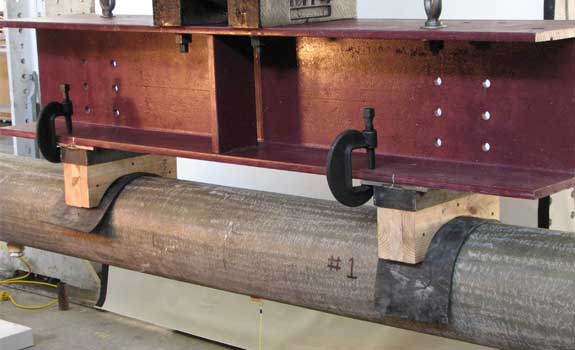

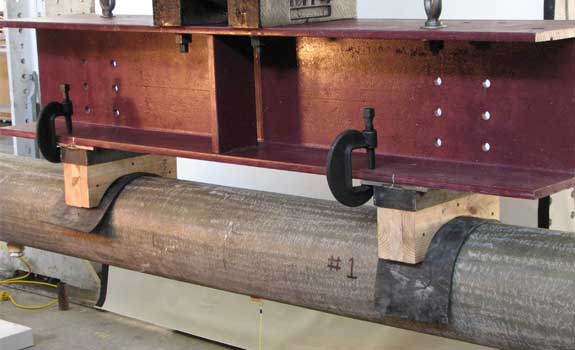

Test Setup: Six each 8″ diameter x 16′ long timber piles were tested in bending using a four point bending setup. To simulate deterioration, five of the piles had an hourglass–shaped cut into them at mid-span. One specimen was left undamaged which was used as a baseline control specimen.

Results: The results of the six pile bending tests proved that all repaired piles exceeded the bending strength of the baseline pile by at least double the maximum load achieved by the baseline pile.

2014 Timber Piles Tested in Compression

Test Setup: : Four each 8″ diameter x 20″ long timber piles with a fiberglass reinforced jackets, grout and carbon fiber grid. One specimen was a plain timber pile with no repairs and used as a baseline control pile. The objective was to evaluate the behavior of the repairs and quantify the additional compressive strength from the repairs vs. the baseline control specimen.

Results: The compressive failure loads of all four pile specimens were significantly higher compared to the baseline control specimen. The average increase in the axial compressive strength was approximately 240%. All specimens withstood 3 to 4 times the failure load of the baseline control specimen.

Please contact Denso for a copy of the complete Texas A&M Independent Test Report. All Testing & Results by: Peter B. Keating, Ph.D. Director of Structural and Materials Testing Lab – Texas A&M University – College Station, TX.

Bending test setup & actuator for the SeaShield Series 400.

Completed bending test – all piles doubled in strength compared to the original unprotected piles.

Compressive test setup.

Bending test setup & actuator for the SeaShield Series 400.

Completed bending test – all piles doubled in strength compared to the original unprotected piles.