Denso Bore-Wrap®

Horizontal Directional Drilling (HDD) and trenchless pipeline installations are critical for crossing roads, rivers, railways, and other High Consequence Areas (HCAs). Once installed, HDD pipelines are inaccessible for repair—making pipeline coating protection essential. While HDD minimizes surface disruption, it exposes pipeline coatings to some of the harshest installation conditions:

- Shear – Coatings disbond under bending stress.

- Abrasion – Constant wear from soil and slurry.

- Impact – Rocks and debris hitting the coating

- Gouge – Sharp objects cutting into the coating during pullback.

Even minor coating damage can create hidden corrosion hotspots, shortening pipeline service life and increasing environmental and financial risk.

Uses

- Horizontal Directional Drilling (HDD) and Boring

- Thrust Boring

- Pipe Jacking / Auger Boring

- Microtunneling

- Sliplining & Relining Projects

- Trenchless Installation

- Mechanical Protection of Field-joint and Mainline Coatings

- Coating Transitions

- Field Joint Coatings

- Shrink Sleeves

- Directional Drilling in rugged or rocky terrain

- Pipeline Integrity Repairs

- High Consequence Areas (HCAs)

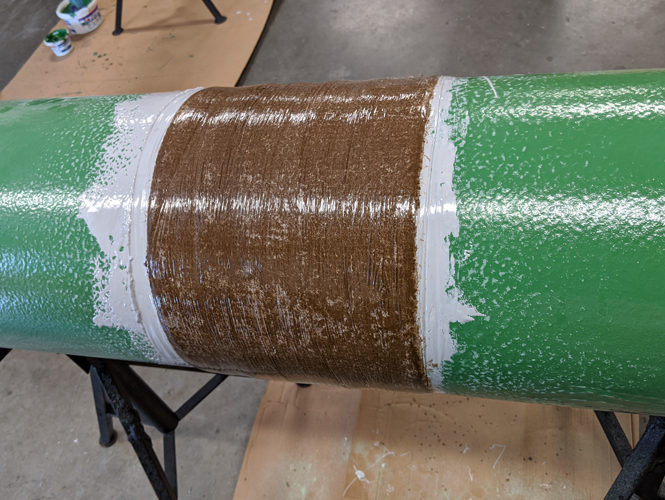

Denso Bore-Wrap® is a field-applied Abrasion Resistant Outerwrap (ARO) engineered to protect anti-corrosion coatings during HDD and trenchless installation. Bore-Wrap is designed to absorb Shear, Abrasion, Impact, and Gouge (SAIG) forces during HDD and trenchless installations. It preserves the integrity of the primary coating by acting as a sacrificial shield.

- Field-friendly application – water-activated, no mixing, cures even in 100% humidity.

- Sacrificial laminate protection – absorbs shear, abrasion, impact, and gouge (SAIG) forces.

- Compatible with all coatings – FBE, 3LPE, 3LPP, epoxy, shrink sleeves.

- Fast curing – ready for backfill in less than one hour.

By acting as a sacrificial shield, Bore-Wrap preserves the integrity of the primary coating and prevents costly coating failures. Investing in Bore-Wrap means avoiding excavation, repulling pipe, spot repairs, or premature coating failure. It preserves coating integrity in High Consequence Areas (HCAs), complies with regulatory requirements for coating protection during drilling, and supports your pipeline’s full service life.

Click to Register to learn more about Bore-Wrap benefits from webinar – Eliminating Hidden Coating Damage in Horizontal Directional Drilling

< Back To Protective Outerwrap Products Page

Request Safety Data Sheets (SDS)- Prevents coating damage

- Rapid application and cure time

- No mixing or VOCs

- Tapered surface profile

- Outstanding abrasion, gouge and impact resistance

- Resistant to aggressive soil conditions

-

Denso Bore-Wrap Application Specification

application instructions

-

Denso Bore-Wrap® Brochure

literature

-

Denso Perforating Tool for Bore Wrap

datasheet

Product FAQ

Why does HDD require additional coating protection?

HDD exposes coatings to SAIG forces (Shear, Abrasion, Impact, Gouge). Conventional coatings alone are not designed for these stresses. This is the harshest method of pipeline installation, requiring the pipe to be dragged through a hole for some duration. Conventional coatings are designed for trenched pipe lays with select backfill getting poured over it.

What does SAIG mean, and why is it important?

SAIG stands for Shear, Abrasion, Impact, and Gouge. These are the four major forces that damage coatings during HDD installations. Bore-Wrap® is specifically engineered to protect against all four, ensuring your pipeline coating survives pullback.

Does the plastic (Poly-Wrap) need to be removed before installing the pipe?

Yes, the poly-wrap is not a structural component of the Bore-Wrap system. It’s sole purpose is to compress the resin during the cure process. If it is not removed, it will begin to tear off inside the whole and possibly create hole obstructions or points that can shield CP. When removing, small bits may get stuck in the resin, they will not impact the performance and can be left on the surface.

What surface preparation is required to apply Bore-Wrap?

The primary task before applying Bore-Wrap is to ensure the surface is clean and free from oil and debris. Use a holiday detector to verify that the anti-corrosion coating is fully intact before applying Bore-Wrap. Bore-Wrap bonds through a combination of surface tension, hoop strength, and compressive strength. These factors/properties are inherent in the products design and will be present regardless of the level of surface roughening done to the underlying anti-corrosion coating. While adding some surface roughening may increase adhesion, it is not always necessary. For specific applications contact Denso for further information.

How do you check the cure?

Bore-Wrap resin hardens as it cures. It is a single component resin that activates with water so no mixing is involved. The fiberglass architecture does not “cure” as fiberglass is already in it’s final state. To check the cure, use a Calibrated Shore-D gauge on the highest point of resin to make sure the resin is cured. Sufficient cure is at a Shore-D of 65 or greater.

How long does it take to apply Bore-Wrap?

Bore-Wrap is a simple application and can be completed with as few as 3 people or as many as 10. The time to apply is usually measured in feet per minute. With 3 people doing a girthweld protection, it is about 1.5 feet per minute. With 6 to 10 people performing a mainline application it is about 3 feet per minute regardless of the diameter. One key element is the volume of water that is available, you can only progress at the speed that allows for the Bore-Wrap to be saturated.

Can Bore-Wrap® be applied in environmentally sensitive areas?

Yes. Bore-Wrap® is water-activated, VOC-free, and cures without releasing hazardous chemicals, making it safe for use near wetlands, rivers, and HCAs.

How many layers of Bore-Wrap® are recommended?

A minimum of two layers with 50% overlap is required for protection. For extreme HDD conditions or rocky soils, additional layers can be applied to increase durability.

Can Bore-Wrap® be used for full pipe encapsulation or only field joints?

Both. Bore-Wrap® can be applied weld joints and can also be spirally wrapped for full line encapsulation in highly abrasive bores.

How does Bore-Wrap® compare to epoxy or liquid-applied AROs?

Unlike liquid coatings, Bore-Wrap® is a composite laminate that resists shear, gouge, and impact forces. Epoxies may resist abrasion but are often brittle under HDD stresses, while Bore-Wrap flexes and absorbs energy. Bore-Wrap is an additional mechanical protection for anti-corrosion coatings and is not a replacement for them.

Does Bore-Wrap® interfere with cathodic protection (CP)?

No. Bore-Wrap® is a sacrificial outerwrap and does not shield CP. Its purpose is to protect the underlying corrosion coating so that CP can function properly after installation.

What coatings is Bore-Wrap compatible with?

FBE, 3LPE, 3LPP, liquid epoxies, shrink sleeves, and other anti-corrosion systems.

How long before the pipeline can be backfilled?

Under typical conditions, Bore-Wrap® cures in under an hour, reaching Shore D 65+ hardness. A simple Shore-D test on the resin surface can confirm cure.

case Studies

view allCan’t find what you are looking for?

If you can't find the information you require, need help understanding anything you may have read, or have a general query regarding our products and services, contact us today and one of our representatives will be in touch to help you with your query.